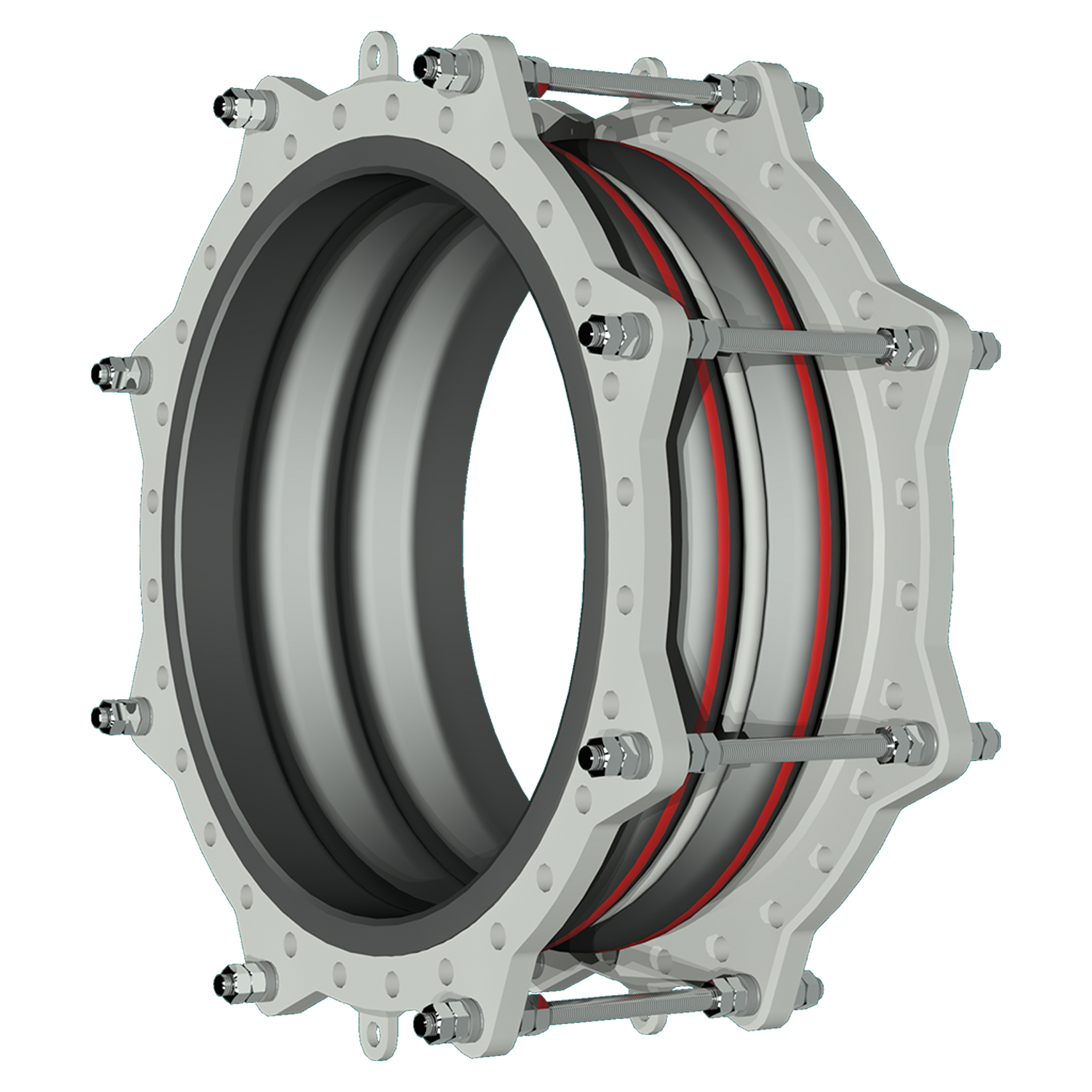

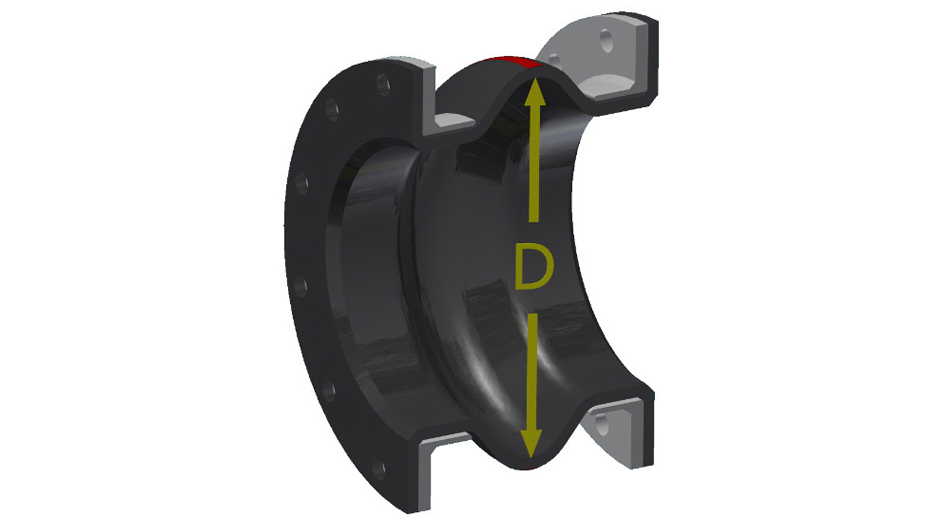

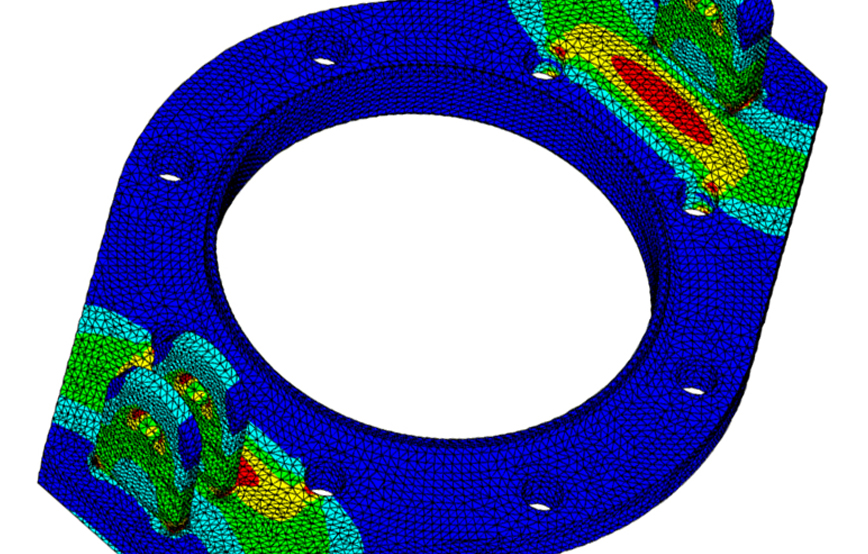

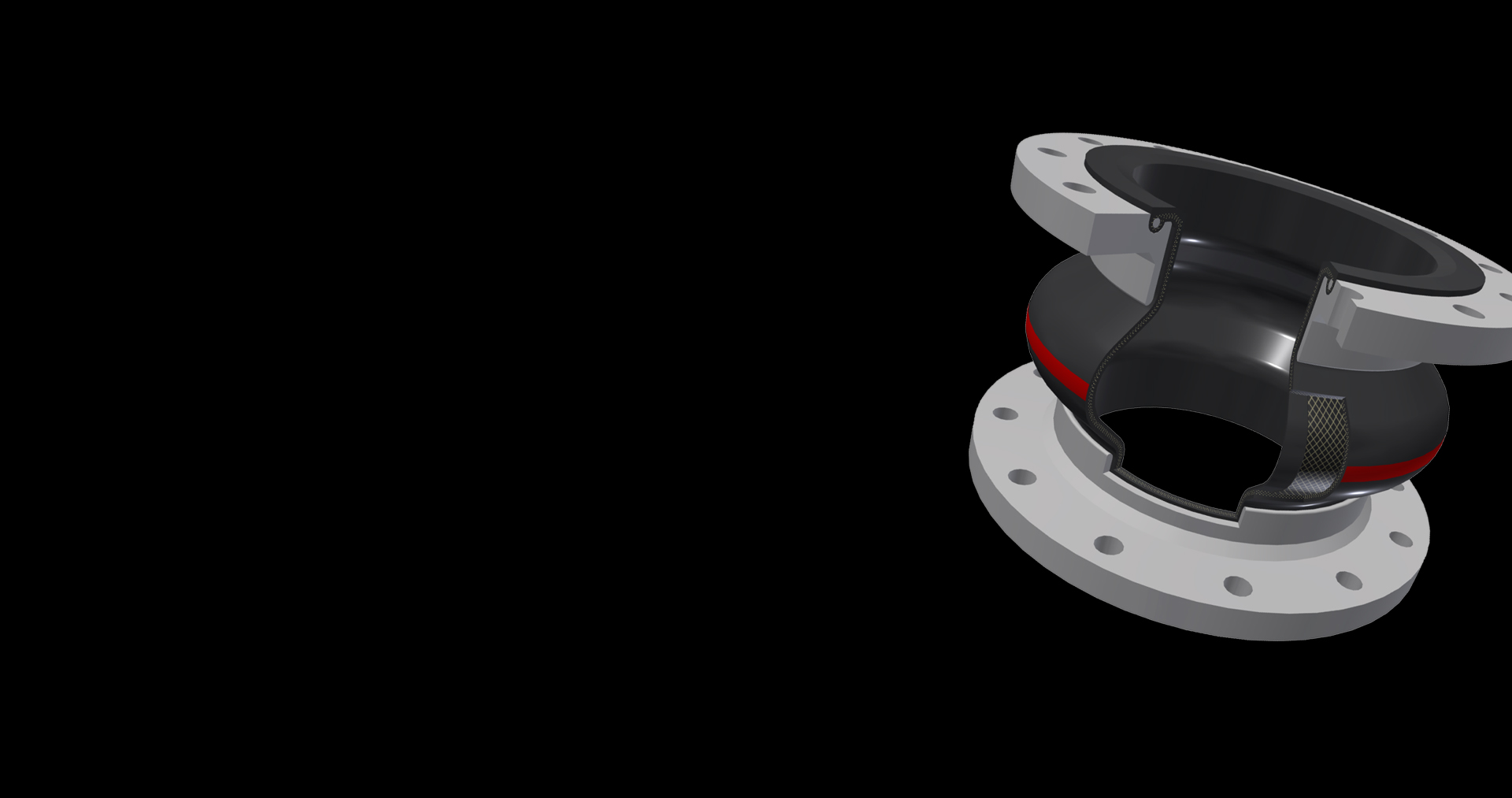

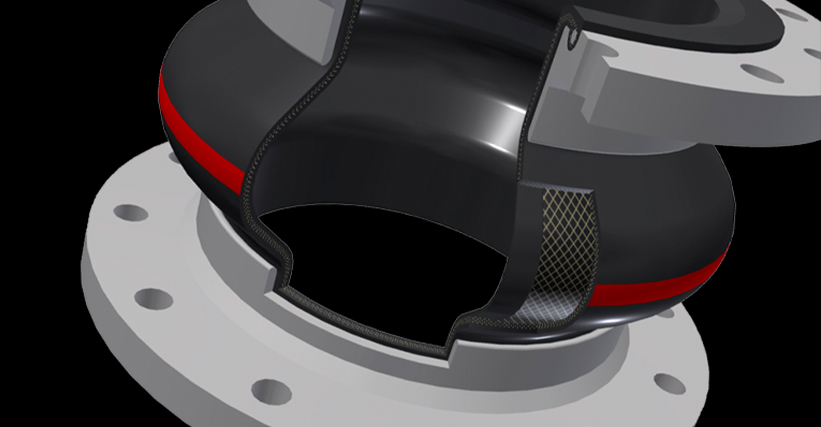

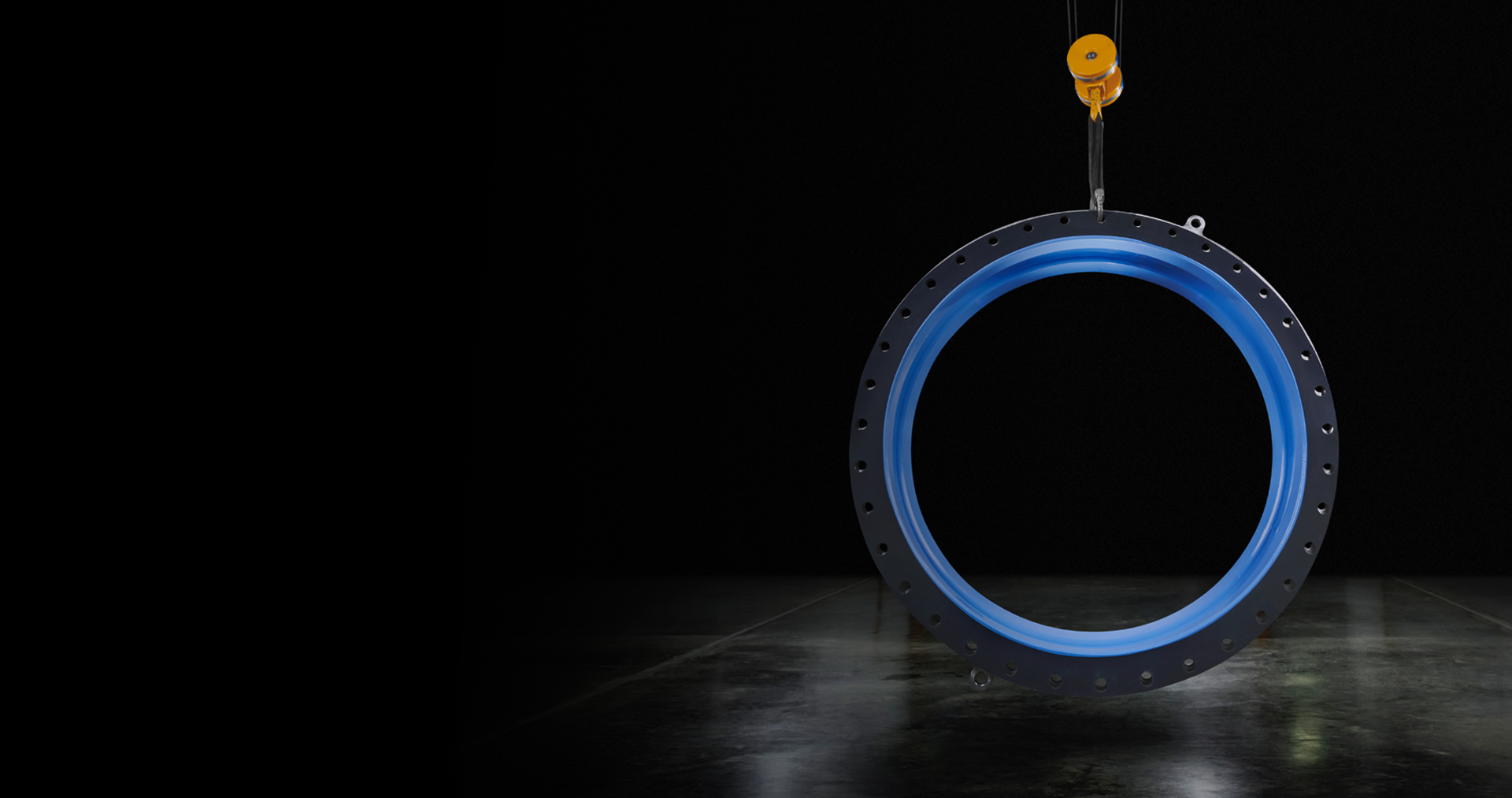

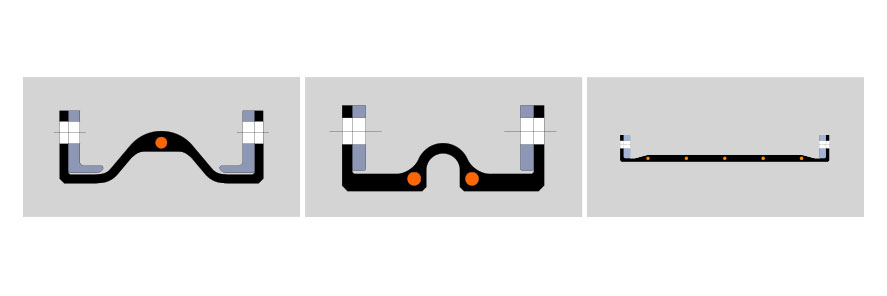

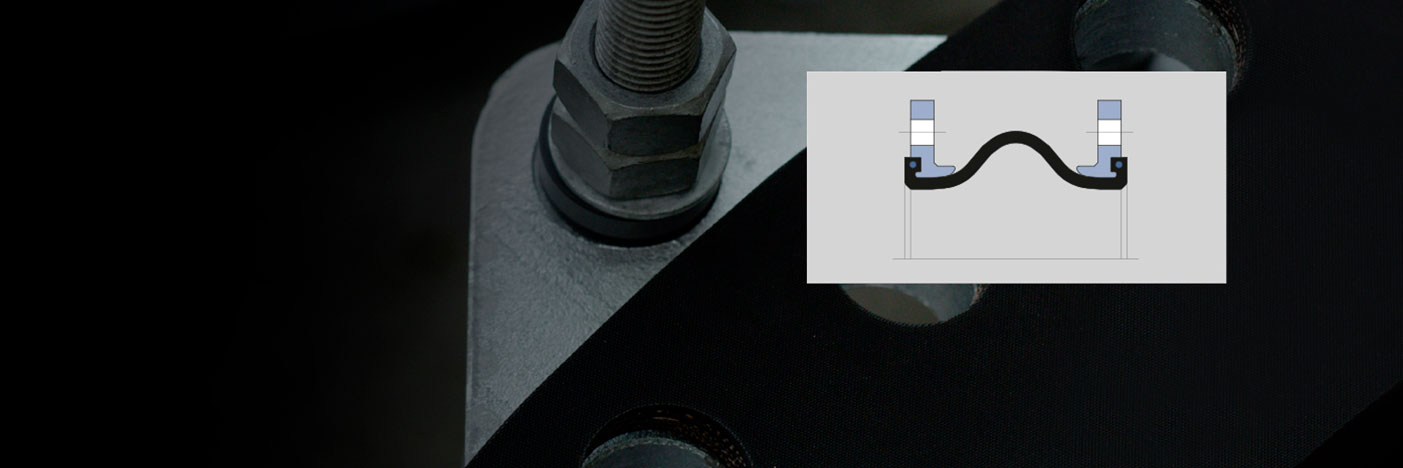

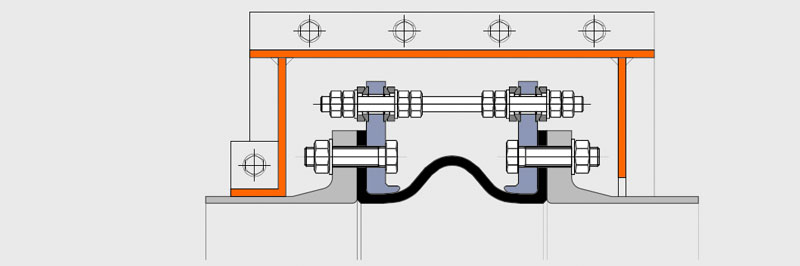

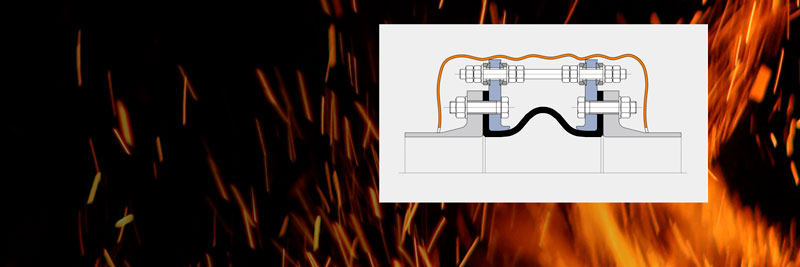

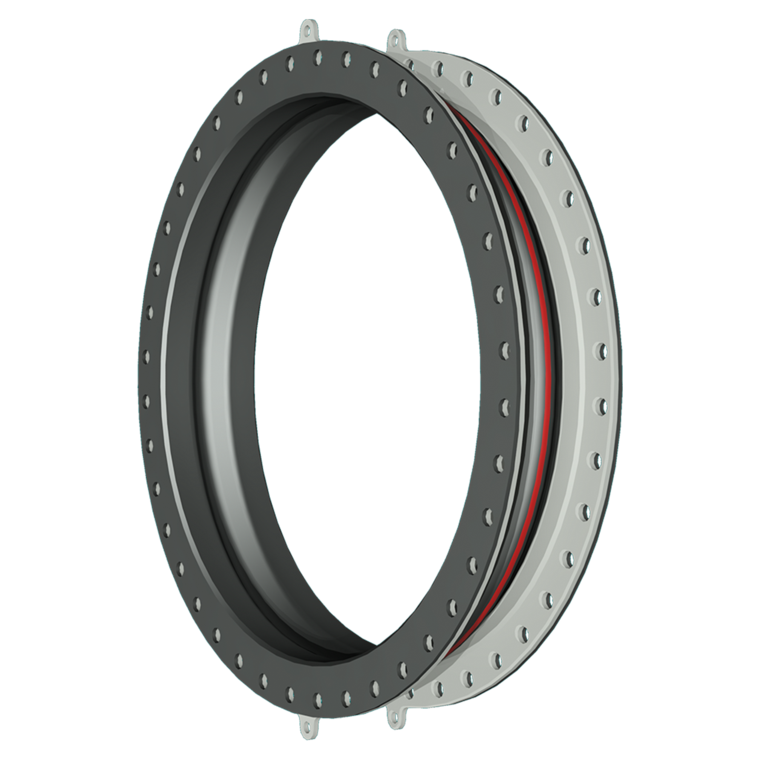

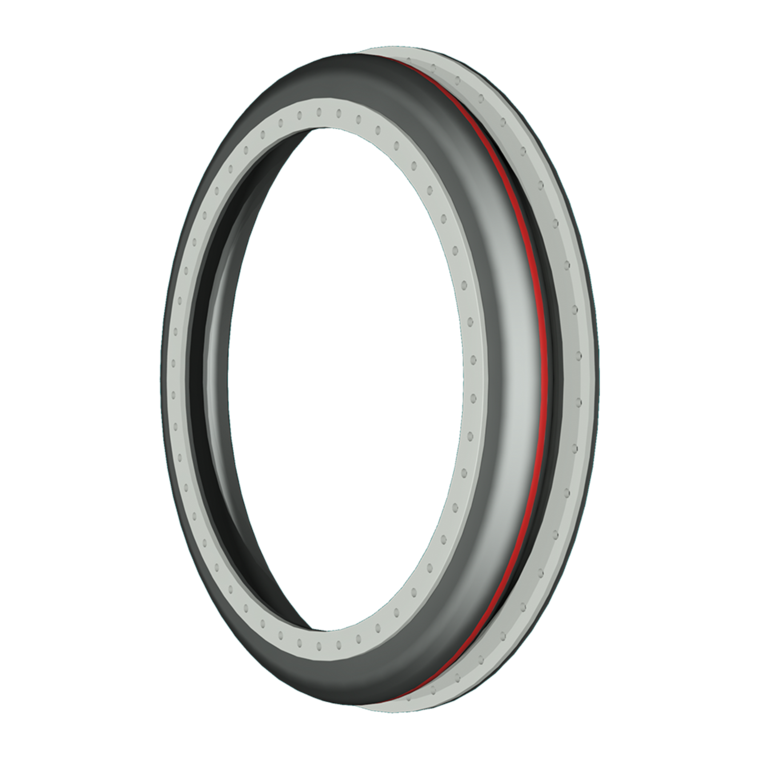

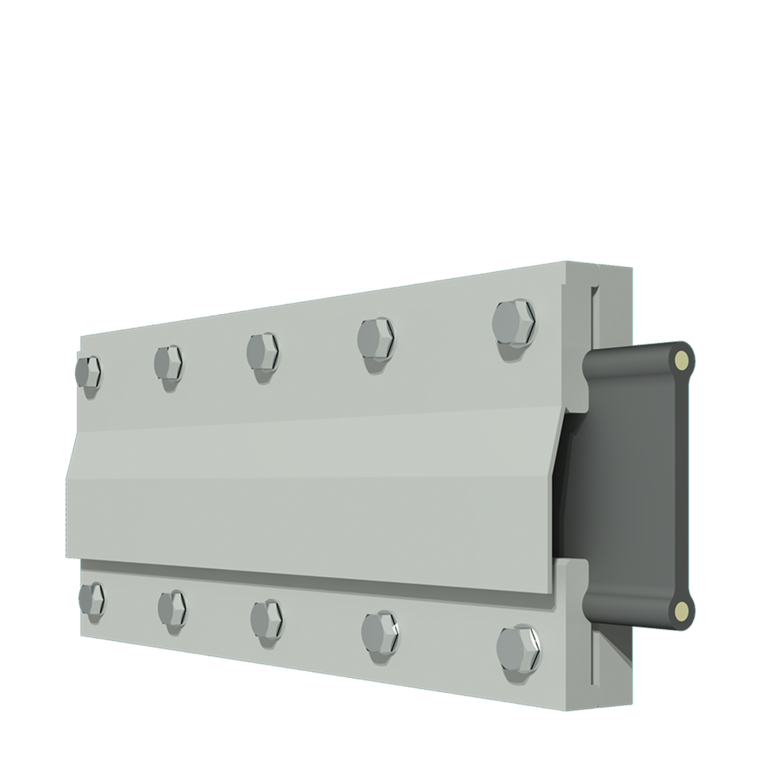

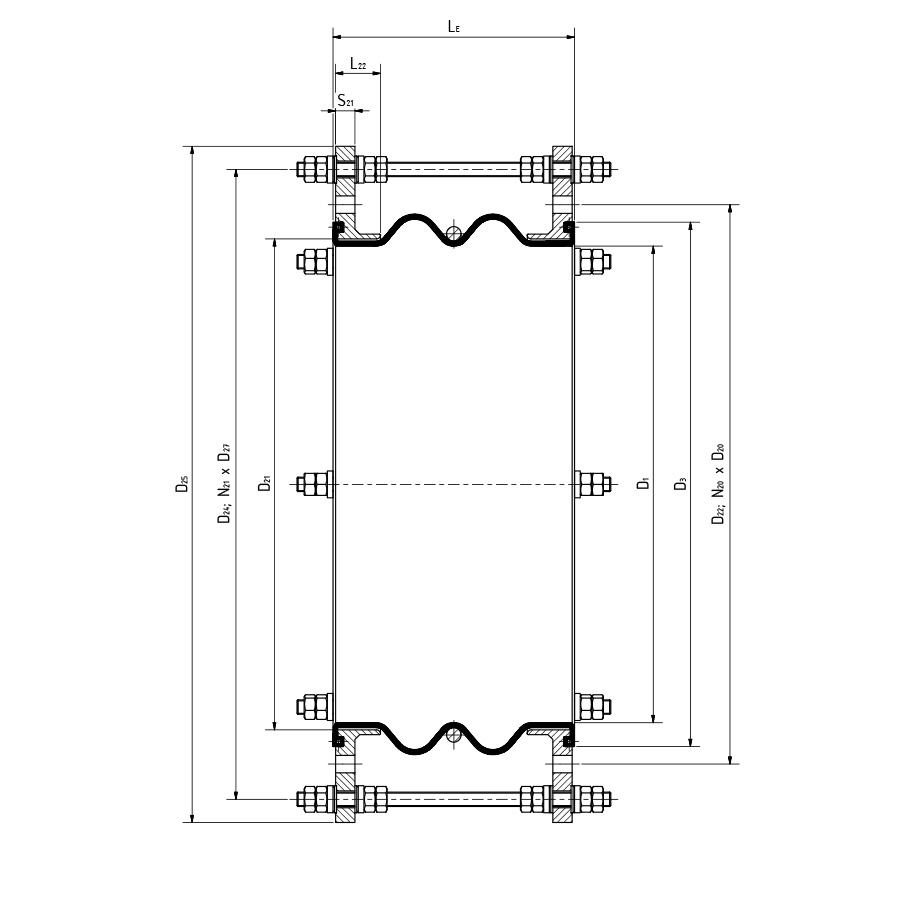

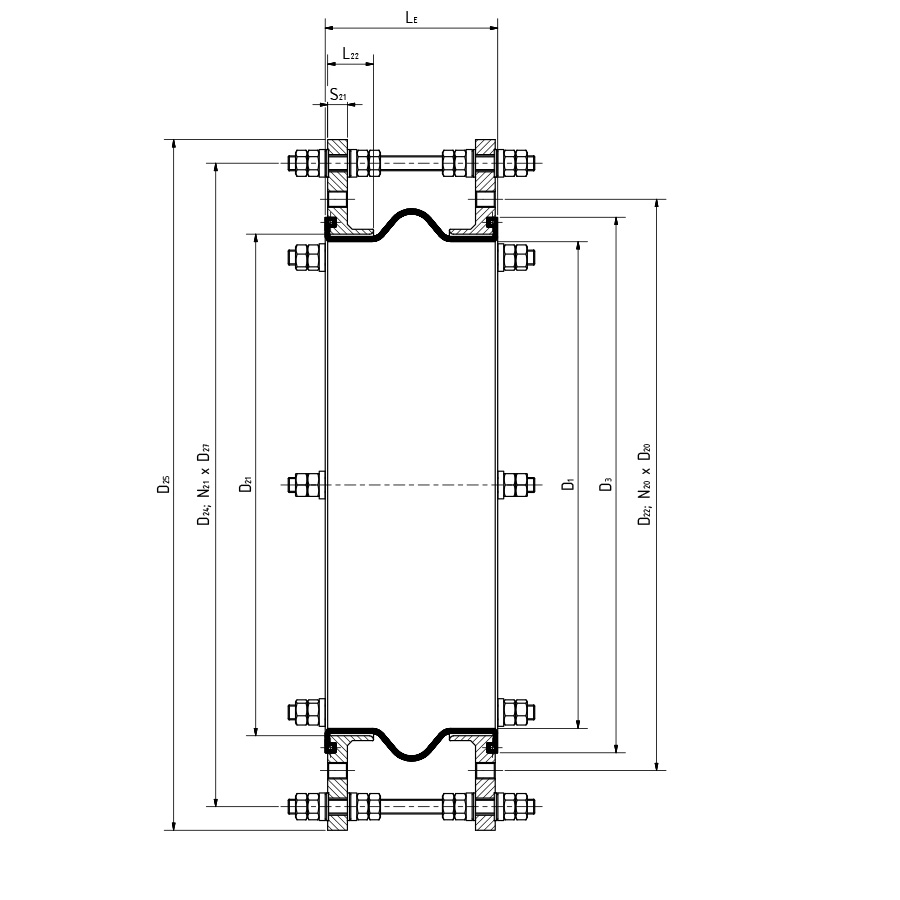

Lateral expansion joint with one or more molded wide arches are designed to absorb lateral movements only, reduce noise and vibration, have a cycle life in the tens of millions, compensate for small axial installation misalignments, provide access to piping and equipment and relieve pipe and anchor stresses.