Vacuum / Support Rings

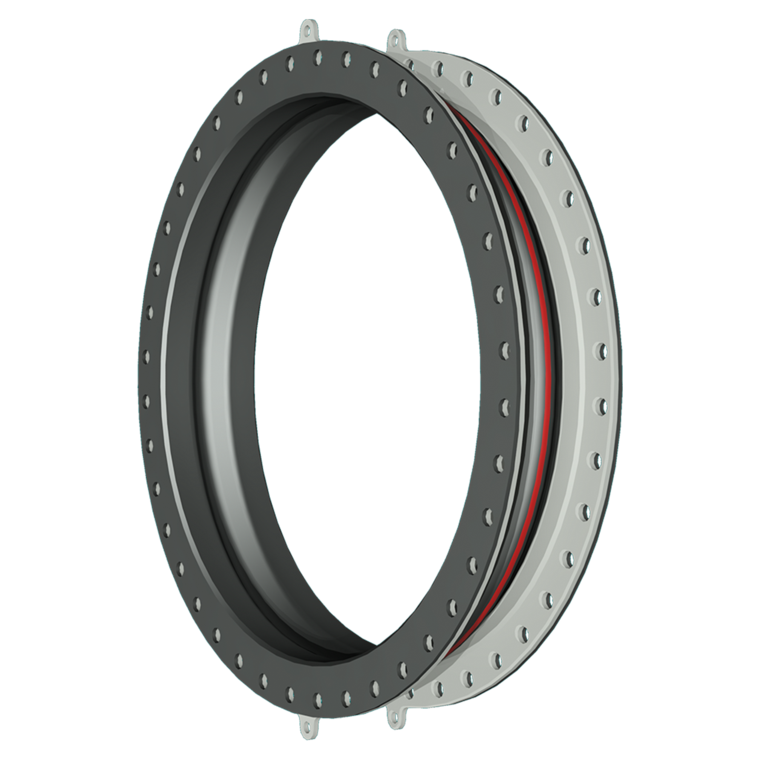

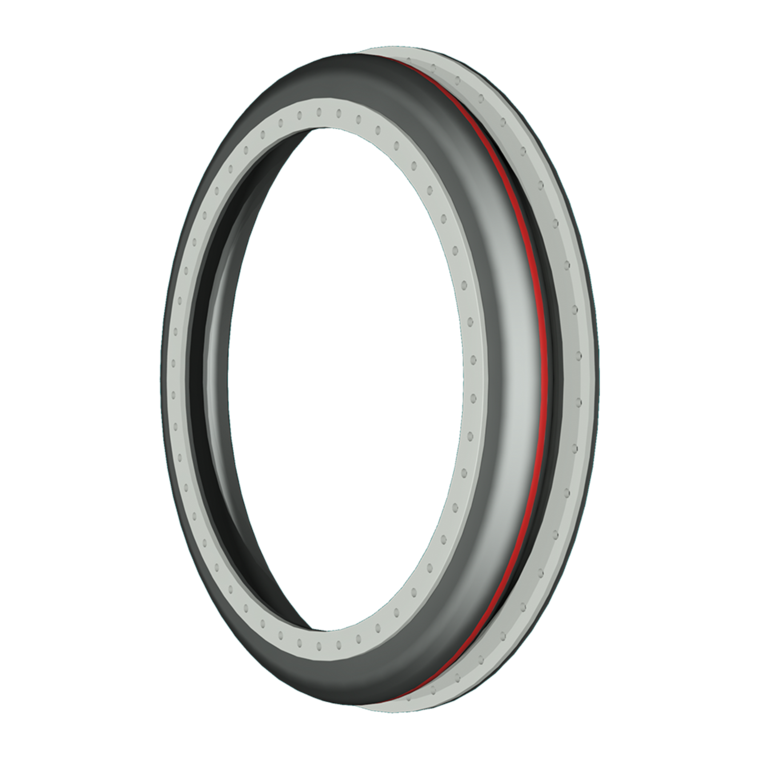

Vacuum rings / spirals can be placed inside of the arch apex and are in contact with the medium flow. Special grades of stainless and super duplex steel with suitable corrosion resistance such as 1.4301, 1.4571, 1.4539 or 1.4410 are used for the corresponding application. More and more common is the design of expansion joints with steel rings embedded in the rubber. It has no media contact, is not washed around by flow turbulence and a cost-effective standard carbon steel grade with high tensile strength and therefore reduced diameter can be embedded. The movement capability of an expansion joint with embedded vacuum ring in the top of the arch is approx. 25% lower than a loose ring inside of the arch. Large bore rubber expansion joints at high design pressures and vacuum are mostly furnished with loose internal vacuum ring which is supplied in several parts. Because of design limits for the ring diameter and transportation issues embedded vacuum rings are in this case uneconomically.

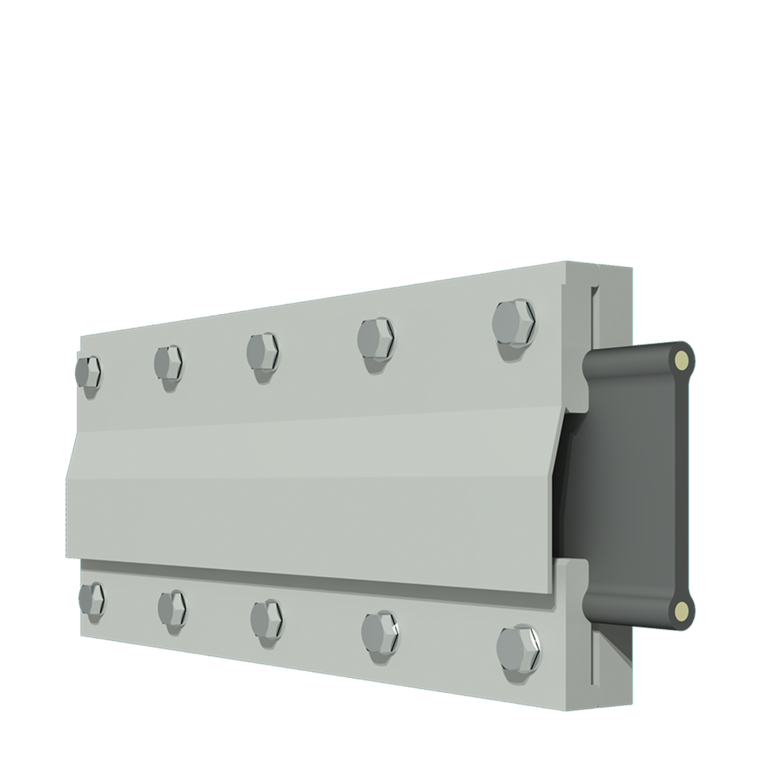

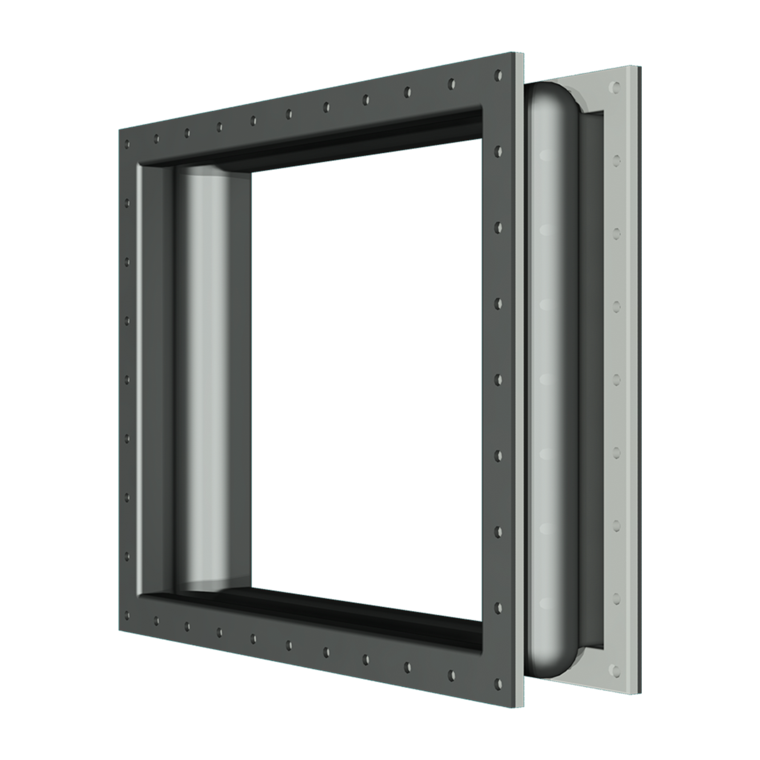

External carbon or stainless steel support rings and ropes are only applicable for multiple arch expansion joint types. Carbon steel support rings are hot-dip galvanized or rubber coated to resist environmental impacts.