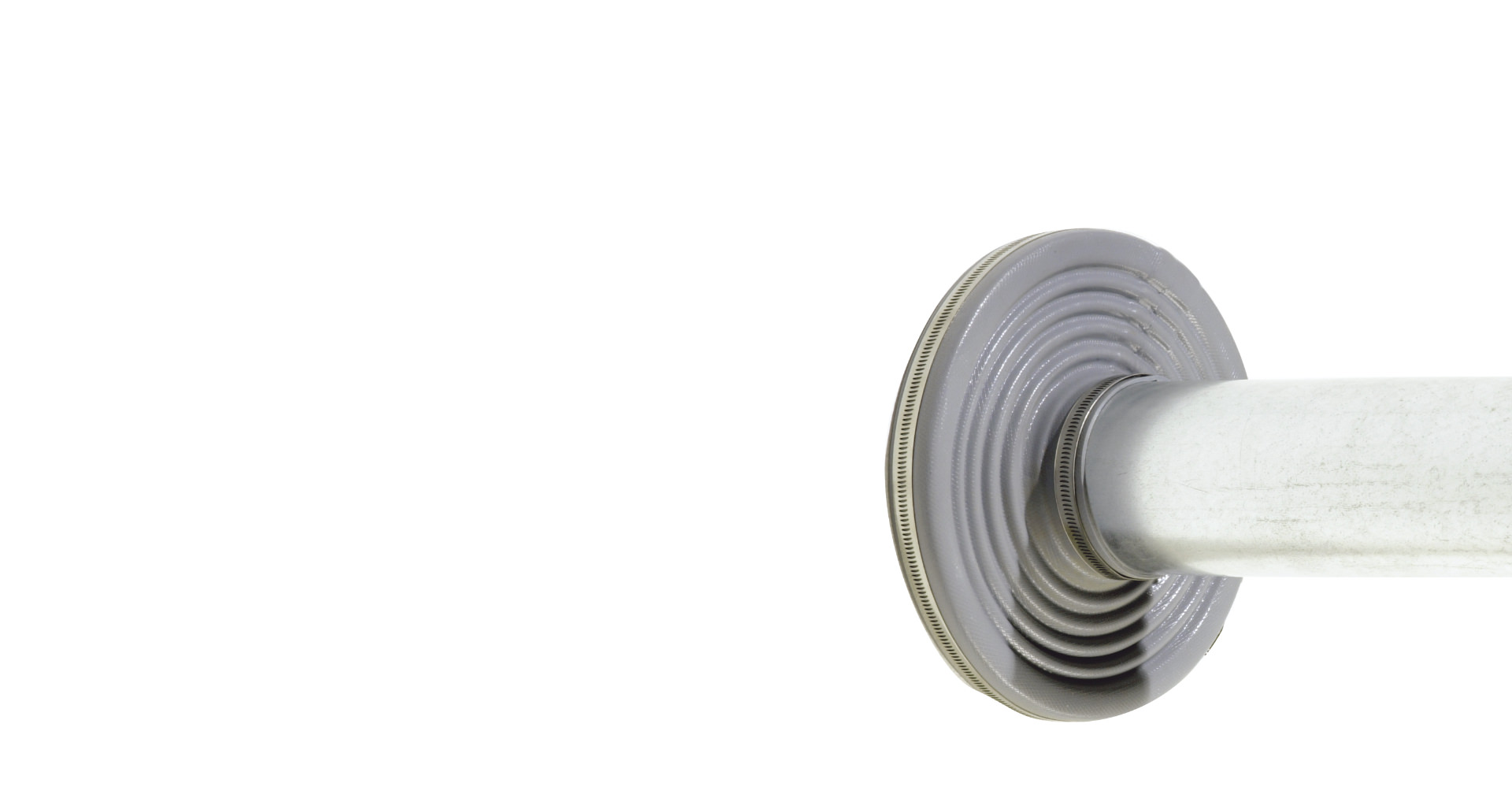

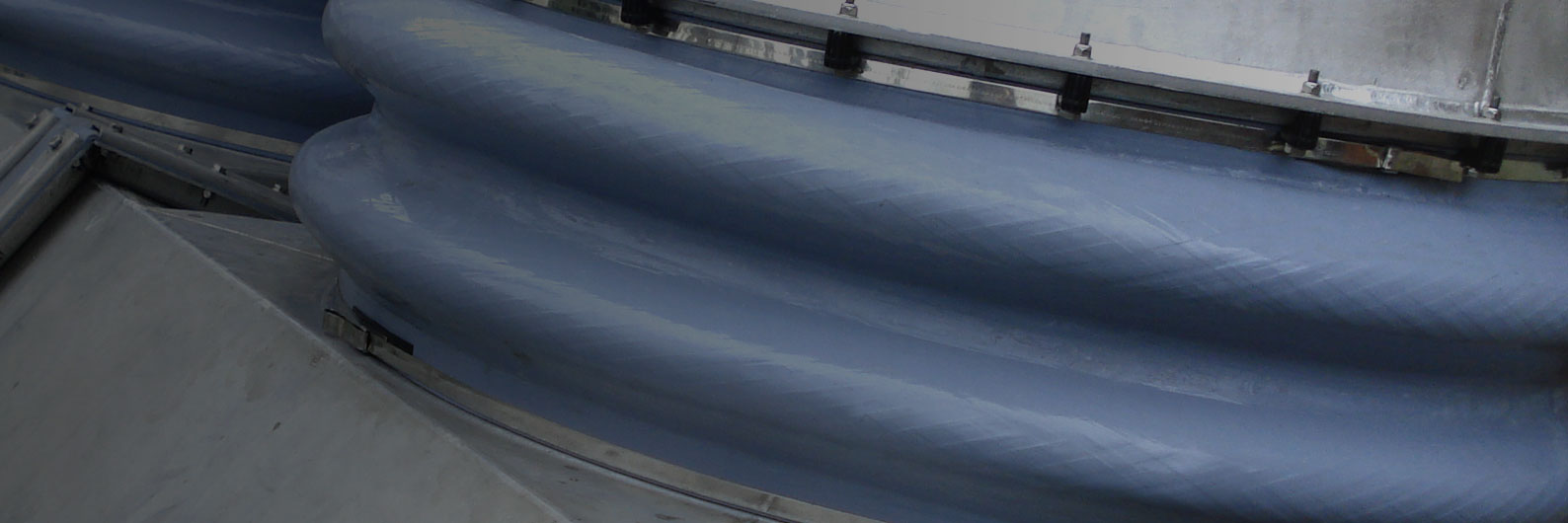

Penetration seals enclose and seal pipes through walls, floors and casings and compensate movements from thermal expansion of pipelines, seismic displacements and ground settlements. They seal against high level of ground water, flooding, rain, air, fire spreading, transfer of radioactivity and splash water from fire water jet. Additionally, they absorb noise, vibration and pipe misalignment.

ditec`s fire protection bulkhead sealing offer fire resistance for 120 min for pipe penetrations through walls and ceilings of wall tubes up to NB 900 and medium pipes up to NB 600. DIN 4102, Section 11 states the following: Pipe penetration bulkheads must be designed such that fire and smoke are not spread through walls and ceilings during the period of fire resistance. The fire resistance period is the minimum duration, in minutes, for the prevention of fire spreading.