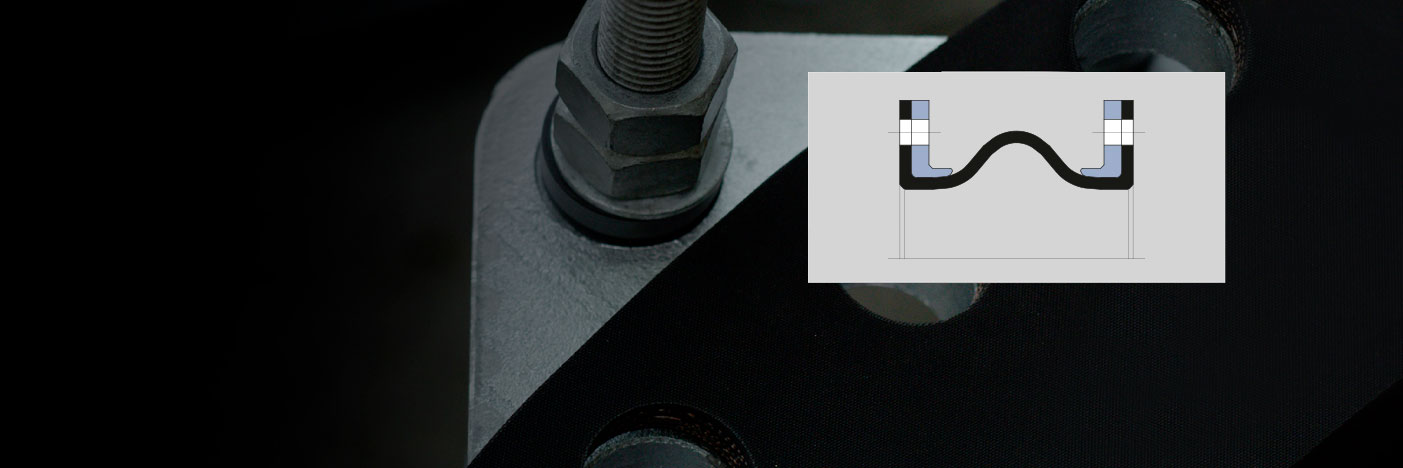

A full face integral rubber flange design with backing flanges is available for types without, with single and multiple arch design. The rubber flange of the bellows is molded in an equal thickness to the flange diameter.

Full face rubber expansion joints are self-sealing. So an additional separate gasket is not required.