Thermal movements along with other external forces and displacements, including ground settlement can quickly exceed allowable pipe and anchor stresses. Rubber expansion joints absorb these stresses and replace them with their own low stiffness (spring rate).

The inherent flexibility of rubber expansion joints permits almost unlimited flexing to recover from imposed movements, requiring relatively less force to move, thus preventing damage to motion equipment. When expansion joints are installed in the pipeline, the static portion of the thrust is calculated as a product of the area of the inner diameter of the arch of the expansion joint times the maximum pressure that will occur with the line. The result is a force expressed in Newton which causes stress on the adjacent pipeline anchors.

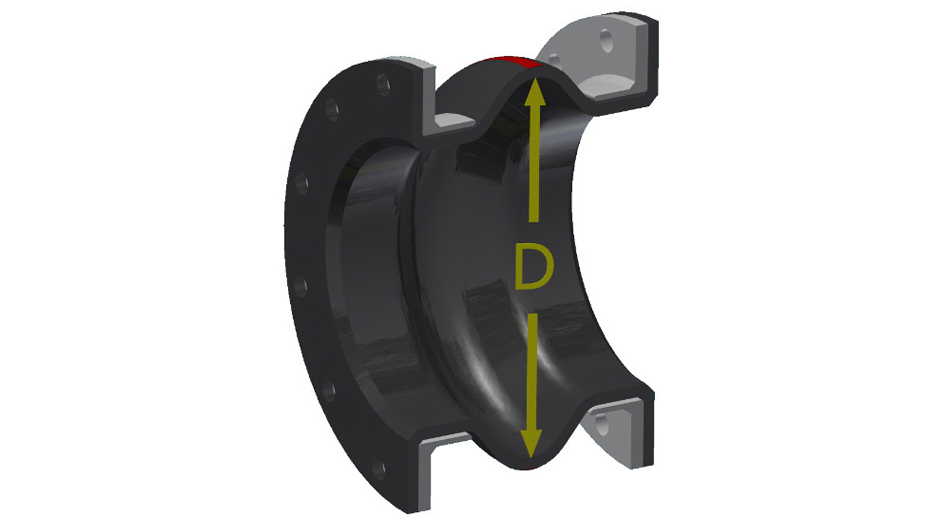

Angular expansion joints receive one or two pairs of hinge plates connected with pins across the expansion joint axis from flange to flange to take the full pressure thrust so that no thrust is transferred onto adjacent pipeline anchors, guides or equipment anymore.